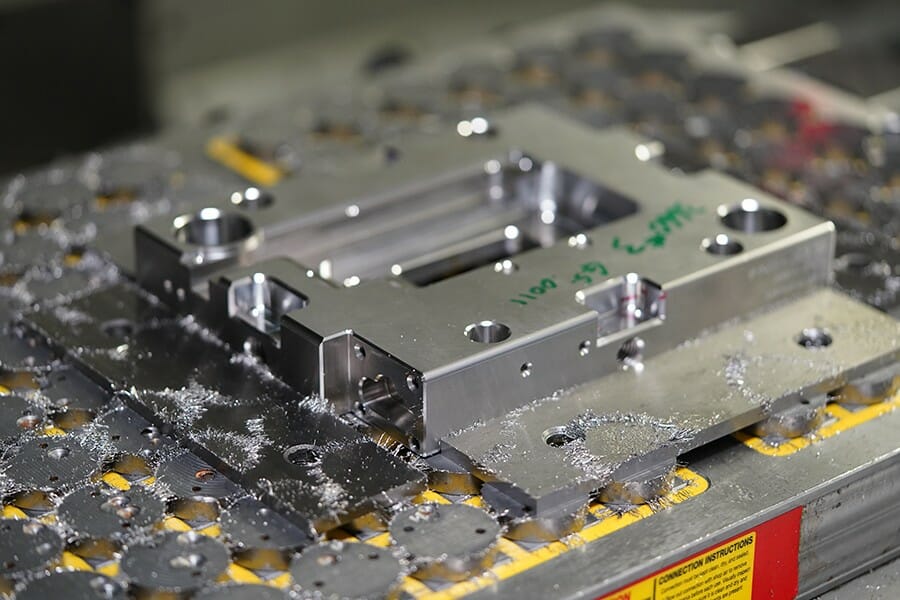

The Injection Mold Making Process

Westfall uses 6 vertical milling centers throughout for a variety of applications from roughing, finish milling, and electrode manufacturing. Roughing is done on the Makino and Haas machines. Finish milling is done on Makino and Sodick machines, hard milling steel to 62Rc. This is accurate and repeatable to within .0001.” The centers are fed with Erowa ERC robots for lights-out machining using 8 pallet positions for increased unattended machining.

Westfall uses several Sodick HS 650L machines for electrode manufacturing because they are linear-motor driven and accurate/repeatable to within .00008”. All finish and electrode centers are fed with Erowa ERC robots for lights out machining with capacity for both electrodes and pallets. Westfall performs 100% inspection of critical machined fixtures and electrodes using the Zeiss CMM (Coordinate Measuring Machine) in a clean room environment using CMM Manager Inspection Software.

Westfall facilitates 4 Sinker EDM’s including 2 Sodick AG 40L machines, featuring linear motor technology providing precision accuracy and reliability. The AG40L features the latest in no-flush EDM technology (flush type vs not flush type), user-friendly control and zero electrode wear combined with increased machining speed.

Sinker EDM capabilities allow us to cut complex profiles into any conductive material tool steel including exotic and precious metals. As sinker EDM uses electrical discharge to cut the profile into the work piece, hardened alloys will not see heat distortion as with traditional machining methods. We can cut work pieces with a minimum part feature of .005”, an accuracy of ±.00004” and a repeatability of ±.00005”.

Both our Sodick and Agie Sinker EDM Centers are connected to Erowa robots for lights out machining that supports multi-cavity, multi-part projects with very tight tolerances.

Let’s talk about your project

Wire EDM

Westfall uses 5 Wire EDM’s including 2 Sodick AG 400L machines that are linear-motor-driven for accuracy and repeatability to within .00004” along with very high reliability. We commonly use Ø.004” wire for day-to-day tight tolerance, high volume components with the ability to run Ø.002″ wire for specific applications. All Wire EDM centers utilize the Multi-Position Erowa Workholding System.

Westfall maintains our commitment to perfection with in-house polish providing the last set of eyes on the product prior to final assembly.

In-house Polish

Westfall maintains our commitment to perfection with in-house polish providing the last set of eyes on the product prior to final assembly.

Mold Assembly

Westfall engineers the fits and clearances during design to ensure true component interchangeability. For each project, Mold Craft provides a fully detailed design package with the optional full inspection documentation.

Quality Certification

We are proud to employ Master Mold Builders who are AMBA-PMBC and AMBA-MMBC certified.

Is Westfall the Right Fit?

Our molds, built with exceptional innovation, craftsmanship and detail, provide many years of service and hundreds of millions of parts. Interested in working with us? Contact us today to discuss your project!

Get in touch today

Want one of our Industry Experts to contact you to discuss your next project? Fill out the form to the right and we’ll contact you today!

Schedule a Strategy Session

Please complete the form below and we'll contact you to discuss a customized solution to fit your needs.